Septa Chair

Elegance in chair design is not solely defined by form—it is a dialogue between the user, the production process and the material. Septa is a rocking lounge chair. It’s a pleasure to sit in and rock back and forth or side-to-side. In the Septa chair parametric design innovations have been combine with large format additive manufacturing, for a scale and immediacy that demand a new kind of sensitivity. The result is a chair that balances structural integrity with visual lightness, where each curve and connection is a direct expression of design craftsmanship, algorithmic precision and careful production. In this context, technology doesn’t overpower craftsmanship—it simply refines it.

Producer: Nagami

Computational Design Partner: Differential

Read more after the images…

100% Recycled PETG

100% Recycled PETG

100% Recycled PETG

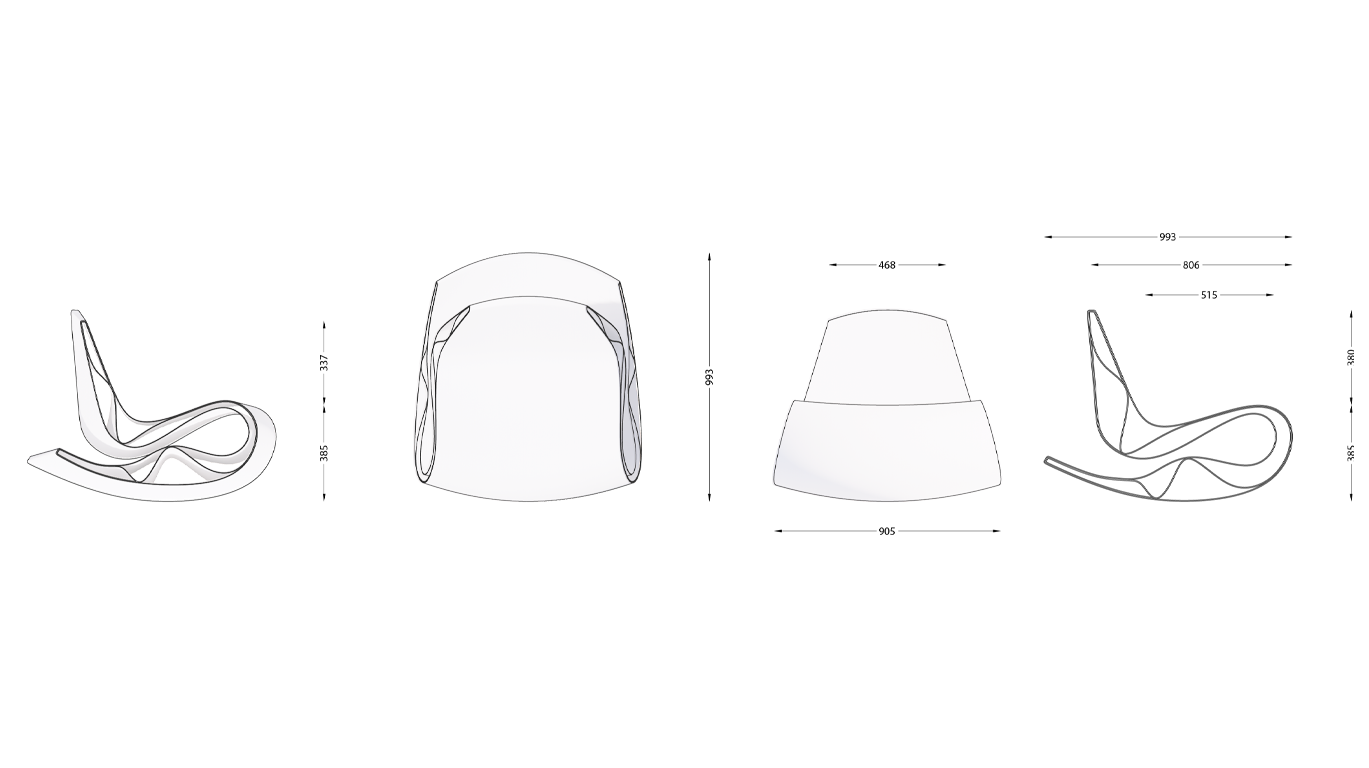

Sizing

100% Recycled PETG

Sketching

Fibre glass reinfocred PETG

Fibre glass reinfocred PETG

Fibre glass reinfocred PETG

100% Recycled PETG

100% Recycled PETG

100% Recycled PETG

100% Recycled PETG

PETG

PETG

PETG

Corkfill PLA

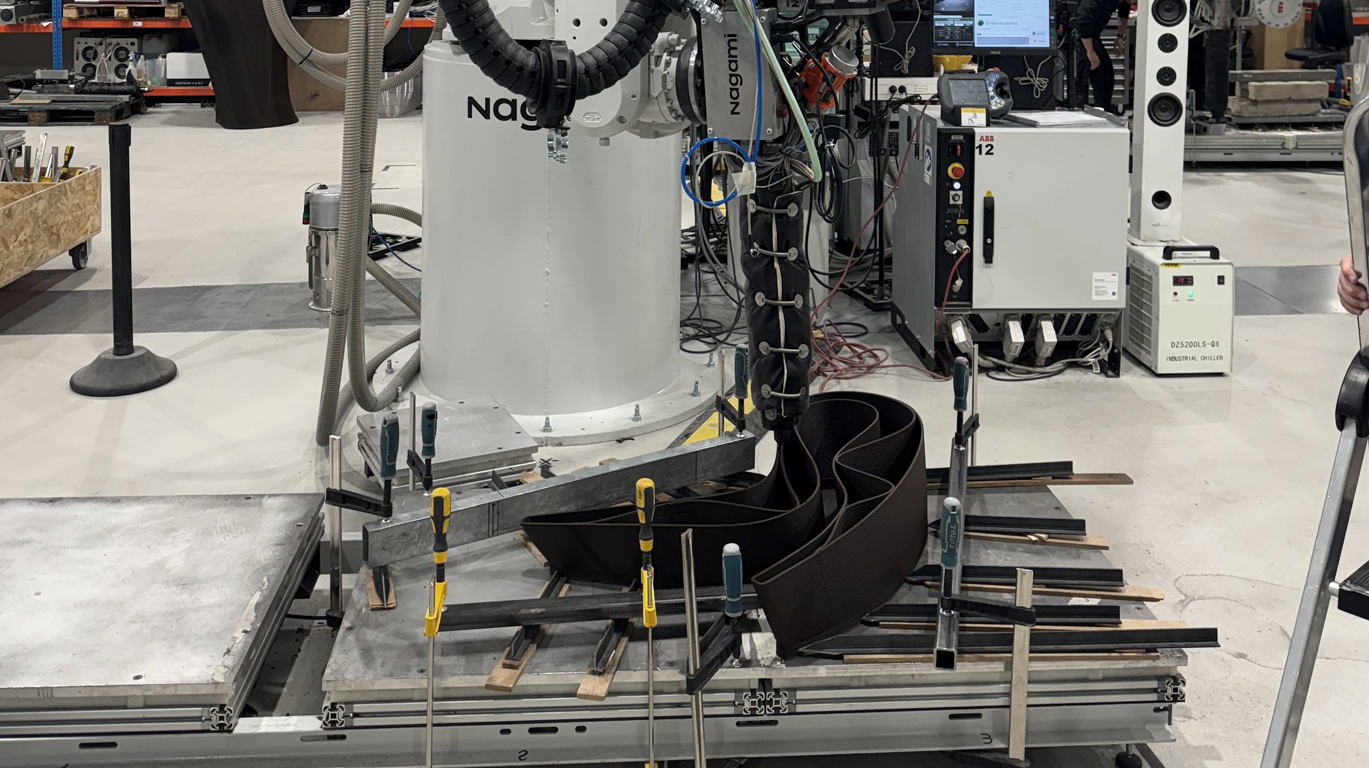

Production @ Nagami

We consider 3D printing as a technology and its specific materials and processes in line with another great invention that changed design in the mid-20th century: fiberglass. Charles and Ray Eames hit the mark in the post-war era, combining fiberglass–the high-tech of the time–with comfort. 3D printing is revolutionizing design just like fiberglass did 75 years ago. In designing a 3D-printed rocking chair, we aimed to create a minimal, lightweight, and comfortable design. The challenge lay in combining elegance with 3D printing on an industrial scale, otherwise known as LFAM (Large Format Additive Manufacturing).

We looked into successful existing rocking chairs, and took note of similarities in the angles of the seat and back and the radius of the rocking rails. As a perk, we wanted our chair to be able to spring and rock in two directions. With these ideas in mind, we explored possible shapes and the 3D printing technology to be used to produce the chair.

Robotic 3D printing is like drawing a house without lifting the pencil from the paper. It needs to be done in one continuous motion, because the material flow can not be stopped and restarted. In this respect, the infill in a 3D-printed product is as important an aspect to consider during the design process as the outer shape, so it was important for us that the infill of the Septa Chair would be an integral part of the design.

The design of the Septa chair is composed of a single surface that wraps around and through itself. As a designer, you create a digital model that is processed by the software managing the 3D printer. Usually, the software generates the most efficient infill. But in this case, we designed the infill ourselves because it is an integral part of the chair design. So, technically, the Septa chair is created by a pattern of layers made of two alternating curves that create a continuous material loop for the LFAM robot.

These technological challenges created an excellent opportunity to work more closely with Nagami and Differential. Because we wanted to do something that had not been done in regular production, we assisted Nagami to expand their normal production process.

Now we are working with Nagami to find the right colorways. Ultimately, they will be capable of printing a Septa chair within a day and, if needed, twenty-one at a time. The Septa chair will be available in serial production and in limited special editions.